Our Projects

In the USA and beyond, our highly professional project teams work together to ensure the rapid, effective on-site deployment of expert personnel to tackle any task.

Select your region:

Easy to erect and quick to strip

Founded in 1826, Furman University is recognized as the oldest private college located in the state of South Carolina. Furman University was named after Richard Furman, who was the first president of the South Carolina Baptist Convention, which first convened in 1814.

Higher degree of customization

Maple Reinders, a renowned Canadian construction company, recently made the decision to choose MEVA Formwork Systems to supply their forming and shoring needs on the Dalhousie Wastewater Treatment Plant, located in the picturesque Niagara Region of Ontario, Canada. Choosing MEVA highlights Maple Reinders’ commitment to provide safety, efficiency and sustainability while building concrete structures for their infrastructure projects.

The tradition continues

Lithko Contracting, ranked number two by ENR’s list of Top Concrete Contractors, has been awarded the new Park-Harrison Student Housing project located on The Ohio State University’s campus.

Up to any challenge

Innovation is the key to growth. It is therefore important to adapt to changing market conditions. A perfect example is the Electronic Vehicle (EV) market, which in 2011 commanded less than 1% of all sales in the automotive industry. By 2021, the EV market had grown to 4.6% and is projected to rise to 50% of all vehicles sold in the United States by 2030.

Archer Western selects MEVA to refurbish Imperial panel fleet

A 2,200 sq. ft. truck load of Imperial arrives at MEVA to be cleaned, buffed, and repaired

Challenges of a road construction project mastered safely

The Ruhlin Company, founded by John G. Ruhlin, has been an integral part of the commercial and industrial market in Northeast Ohio since 1915. The company expanded into the civil market in 1955, constructing bridges, roads, sewers, and wastewater treatment facilities throughout the State of Ohio. In 2006, the Structural Division was added to complement the Heavy Division.

Cornerstone Builders selects MEVA to build TCO fertilizer storage

Cornerstone Builders Ltd., established in 1970, has over 50 years of successful design and build experience in both the commercial and industrial food service sectors. According to their website, Cornerstone proudly displays their core values of communication, accountability, consistency, and teamwork. It was a privilege to team up with Cornerstone on this agriculture project by providing forming and shoring equipment, along with engineering and onsite support.

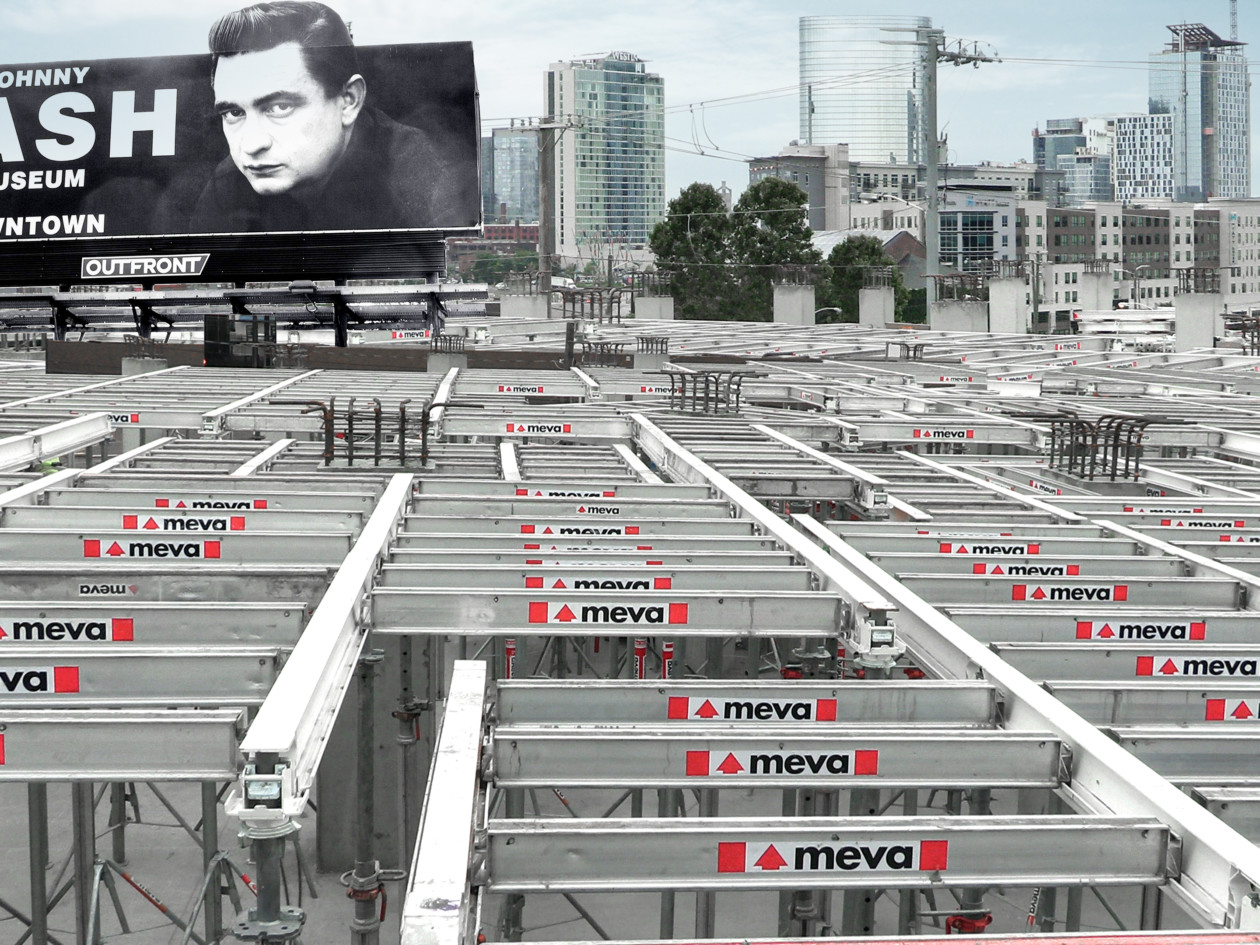

Flexible slab construction

The unusual slab design for a multi-use building in Nashville, Tennessee, was completed faster and easier with the help of the MEVA HN drophead slab formwork system.

New Corporate Headquarters in Grand Blanc

The $10 million headquarters will retain 112 existing jobs to the new facility and create 52 additional positions.

Saving labor, time, and equipment

As the requirements on construction sites vary, construction companies need flexible formwork and support systems. Ideal solutions convince through a high level of efficiency, simple handling, durability, and combinability. These characteristics are decisive for a high level of cost-effectiveness, rapid construction progress, and sustainability – all guaranteed when using the cost-efficient and flexible MEVA32 shoring system.

Top aircraft engine manufacturer

Walbridge, a full-service construction company headquartered in Detroit, Michigan, was selected by Pratt & Whitney to build the structure.

Wayne Brothers rely on MevaLite and SK150 bracket application

Wayne Brothers, one of MEVA’s original customers, was awarded the fermentation tank structure for a new brewery in Columbia, SC. This brewery will be one of the largest breweries built in the United States in over 25 years. The project scope consisted of a cast-in-place tank structure that needed to be built in 90 days so that the remaining building structure could be completed on time.