Select your region:

Slab Formwork

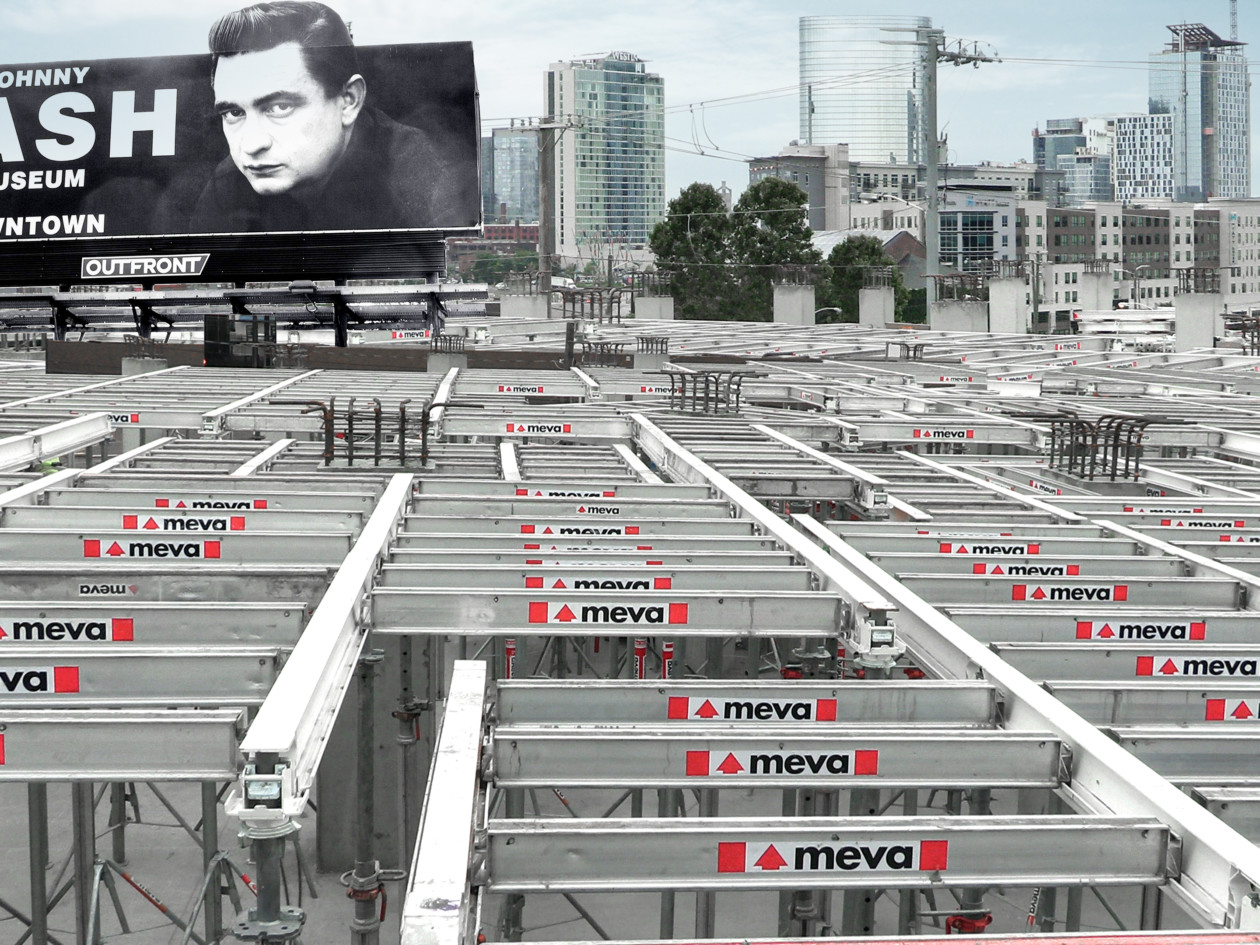

MEVA HN

Fast, efficient, labour-saving solution for concrete slab construction

Ideal for complicated shapes

MEVA HN slab formwork is easy to adapt to changing slab layouts. The secondary beams can be placed and slide freely within the primary beams and adjusted to accommodate complicated shapes and provide more flexibility around columns and demanding geometries. MEVA HN’s innovative design means that if the project design does not allow one more primary beam to fit in the beam row, you can simply change the assembly direction by 90°. The MEVA HN slab forming system features drop heads for early stripping of beams and facing while props remain to support the concreted slab. That allows for a fast cycle process and material savings up to 40%. Designed for seamless integration with the MEP and MEVA32 system, MEVA HN is the versatile choice you need for your project.

Got a specific enquiry about Meva HN?

Why not call our team on +1 937 328 0022

Easy to use

Primary and secondary beam method

- Assembly begins in a corner for easy formation in both directions; primary beams are assembled parallel to the longer wall

- Ability to switch forming direction at any time

- Primary beams can be connected 90° to another primary beam so the direction can be changed to form

- around obstacles such as columns and shear walls

Less compensation areas are required

- Because the secondary beams can be placed into the primary beam anywhere along its length and are not on a fixed grid, less filler areas are necessary

MEVA drop head

- Allows for faster stripping and cycling

- The drop head permits lowering of the formwork by 7½” (19cm)

- Only the post shores with drop heads remain in position to support the weight of the slab until the concrete is strong enough to support its own weight

Adjusts for length and unusual geometries

- If the building design does not allow one more primary beam to fit in the beam row, you can simply change the direction by 90°

Complete formwork solutions

- Use your choice of facing

- Achieve a wide range of slab thicknesses

Simple solutions for complex designs

MEVA HN’s ability to place a primary beam perpendicular to another primary beam means it forms easily and efficiently. It is ideal for:

- All typical slab applications

For more detailed technical information please refer to the download tab which contains PDF information about this product.

| Technical Information | |

|---|---|

| Materials | Aluminium. |

| Widths | 40cm, 60cm, 80cm and 160cm. |

| Lengths | Primary Beam: 270cm, 210cm, 160cm and 80cm. |

| Slab Thickness | Wide range of thicknesses possible. |

| Grid | Grid Independent. |

| Drophead Stripping | Yes. |

| Protective coating | Powder coating for high ease of cleaning and reduced concrete adhesion. |

| Assembly Method | Primary- and-secondary-beam method (HN). |

| Facings | 3S, Plywood. |

| Shoring | MEVA32, MEP, Props. |

Labour saving

MEVA HN slab formwork is very easy to adapt to changing slab layouts.

Change direction

MEVA HN primary beams can be connected 90o to another primary beam changing direction to form around obstacles

MEVA provides a wide range of downloads. Here you will find product information, instruction manuals and much more.

For some downloads we may ask you for your email address so we can send your download to your chosen email address. For your convenience these downloads relate directly to this product. You can also find a full range of pdf downloads here..

Related products and accessories

All MEVA systems are designed to be compatible, saving you time and money. We think you might find these products useful.

MEVA32

MEVA32 is a strong and flexible shoring system designed to suit many different shoring applications, and save labor, time, and space on the job site.

MevaDec

Our latest MevaDec slab formwork system is lightweight and easy to use. It is not bound to a rigid grid pattern, meaning that it can be adapted to suit any building layout and any slab thickness.

MevaFlex

Economical and tried-and-tested, MevaFlex conventional slab formwork provides great flexibility and efficiency.

Our Projects

Examples of projects in your region and around the world

Let our team help you select the right product.

Talk to one of our MEVA formwork specialists, we can help you with all your formwork needs from the ground up. Let us help with your next formwork project.

Subscribe to the MEVA newsletter

MEVA news, worldwide projects and tips & tricks from formwork professionals, digitally and directly to your inbox.